Efficient and Reliable Material Handling

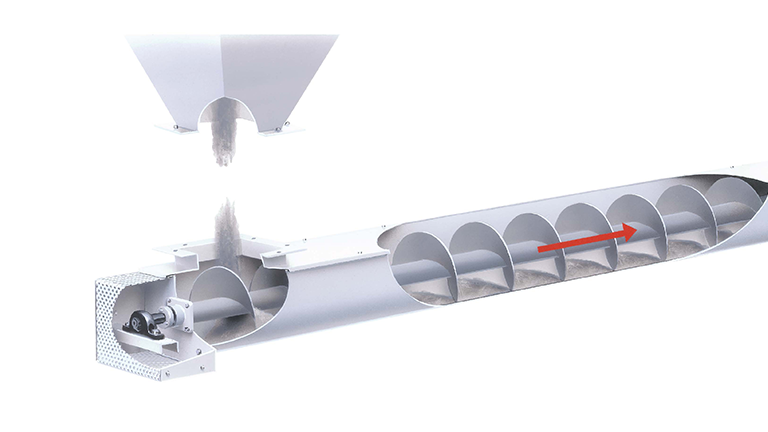

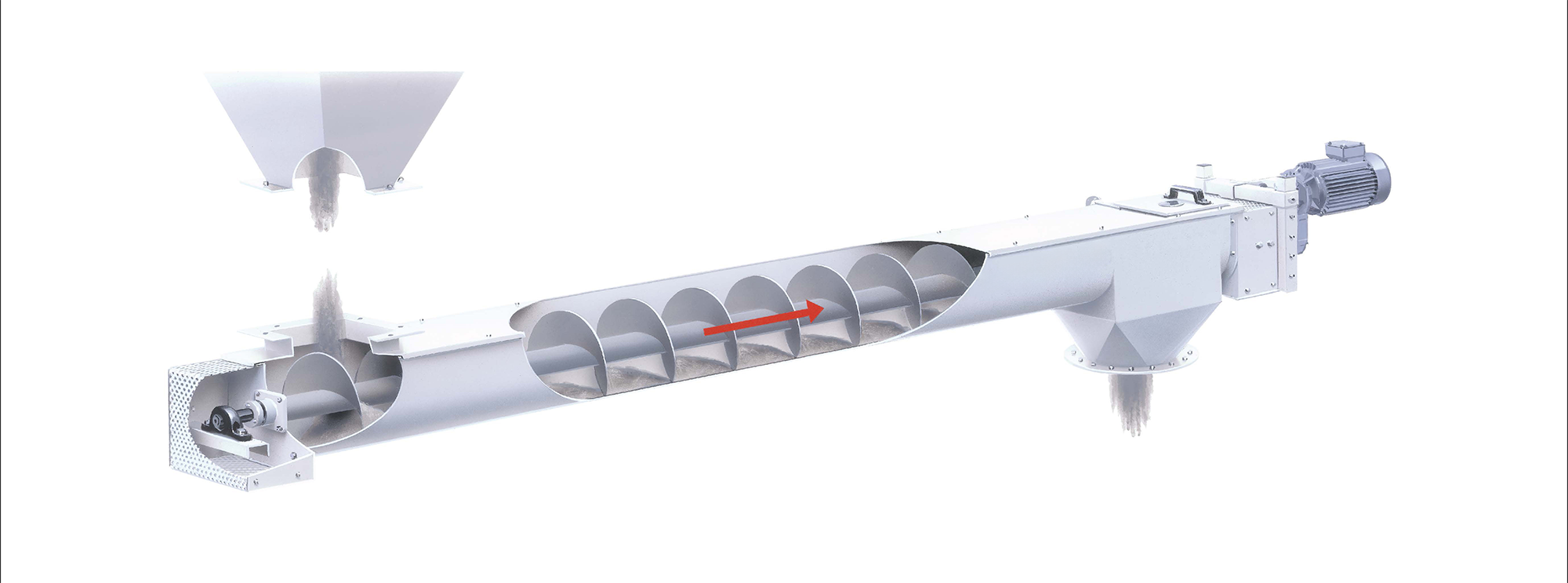

Cimbria’s screw conveyors, also known as auger contect screw conveyors, are designed to transport dry bulk materials such as grains, flours, animal feed, and fertilizers with exceptional efficiency. By rotating a screw within a trough, these conveyors move materials smoothly and reliably, requiring minimal maintenance. Their robust design ensures 24/7 operation, making them indispensable for a wide range of applications.

Versatile Screw Conveyor Types

Cimbria offers a variety of screw conveyor types to meet diverse material handling needs. These include:

Trough Options: Choose from U-troughs, tubular housings, or custom-designed troughs to suit specific applications.

Flight Options: Cimbria Contec manufactures all flights fully welded on the transport side. For hygiene, flights can be made from stainless steel and fully welded on both sides. Standard flights are available rolled or from pressed plate for greater strength. Design options include variable pitch or tapered flights to control product flow, paddle flights for mixing products, and ribbon flights for sticky products.

Benefits of Cimbria Screw Conveyors

Cimbria’s Screw Conveyors are customizable, efficient, and straightforward. They offer a cost-effective solution for moving dry bulk products quickly and gently. Their compact design and flexible configurations allow seamless integration into any material handling operation, even in space-constrained environments.

With their simple design, Cimbria screw conveyors are easy to operate and maintain, requiring minimal downtime. Openable panels enhance convenience for cleaning and maintenance. These conveyors significantly boost productivity at a low cost, making them a vital component of bulk material handling.

Choosing the Right Screw Conveyor

To choose the right screw conveyor design for your operation, it’s important to consider several factors, including material density, particle size, and capacity and flow rate requirements. Be sure to consult with our experts with experience in process flow design to determine the appropriate specifications for your operation.

Shaft Free Flights

When conveying products with long-fiber characteristics such as sludge or screenings, a shaft free flight will be an obvious choice. These can be delivered in special steel with a length of up to 12 meters.

Stand Off Bearings and Adjustable Packing Boxes

Used when conveying abrasive products, powders, or when the temperature is above 90°C. Available with different packing materials and oil rings depending on the product type. Stand off bearings and adjustable packing boxes are standard on SUH and SOH models, with additional choices for SU and SO models.

Individual Adaptation = Flexible Solutions

At Cimbria, we encourage close collaboration between the customer and our experts in the sales and technical departments to ensure the most suitable engineering conveying solution is proposed. This ensures that the customer’s screw conveyor design parameters are met within budget. The choice of the correct Cimbria screw conveyor model with additional optional equipment and design will ensure the best production and engineering practices for a quick return on your investment.

Optional Equipment and Designs

The combination of product wear and flow characteristics, capacity requirements, duty, safety, and the installation environment are all significant factors when designing the appropriate conveying solution. A wide range of optional equipment and designs within the Cimbria screw conveyor standard manufacturing schedule is available to provide the right equipment for your processing needs.

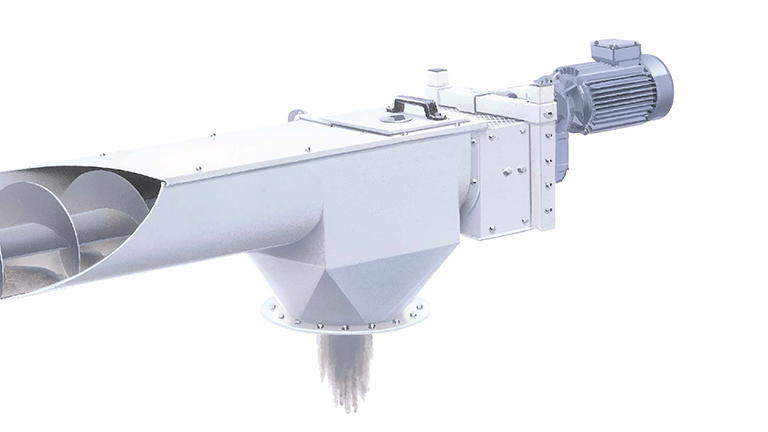

Openable Bottom: For easy access during the cleaning process, the screw conveyor is equipped with an openable bottom with spring locks and a safety microswitch to isolate the drive. Suitable for the SU and SO models.

Openable Cover: Used for ease of access during the cleaning process and for regular inspection. The cover is equipped with spring locks and a safety microswitch to isolate the drive. It can be combined with the openable bottom and is suitable for all models.

Safety Flap and Inspection Door: The safety flap is mounted on the screw conveyor at the outlet end to protect the machine in the event of a blockage. The safety microswitch isolates the drive when the flap is opened for inspection, or a blockage occurs. Generally supplied as standard on all models.

The Drive

Cimbria supplies hollow shaft direct drives as standard, mounted with a substantial torque arm frame at the drive or tail end. They can also be supplied with direct drive coupling.

Cimbria delivers a full range of world-class conveying equipment and solutions for agricultural bulk goods like seed, grain, feed, and fertilizer.

Read more about Cimbria's Screw Conveyor here.