Cimbria Complete™

Our process is designed with our customers at the core. From vision to reality and beyond, our team stays connected with yours.

About

Cimbria is one of the world’s leading companies within industrial processing, handling and storage of grain and seed, as well as animal feed, foodstuffs and other bulk products.

Industrial Application Sorters

Bring your Sorting to the Next Level

Industrial Application Sorters

Bring your Sorting to the Next Level

Our Industrial Application Optical sorters are

- Highly Efficient: Designed for maximum throughput in sorting plastics, minerals, and metals.

- Versatile: Ideal for recycling PVC, PET, HDPE, and various car scraps.

- Cutting-Edge Technology: Boost recovery rates and minimize contamination with advanced sorting solutions.

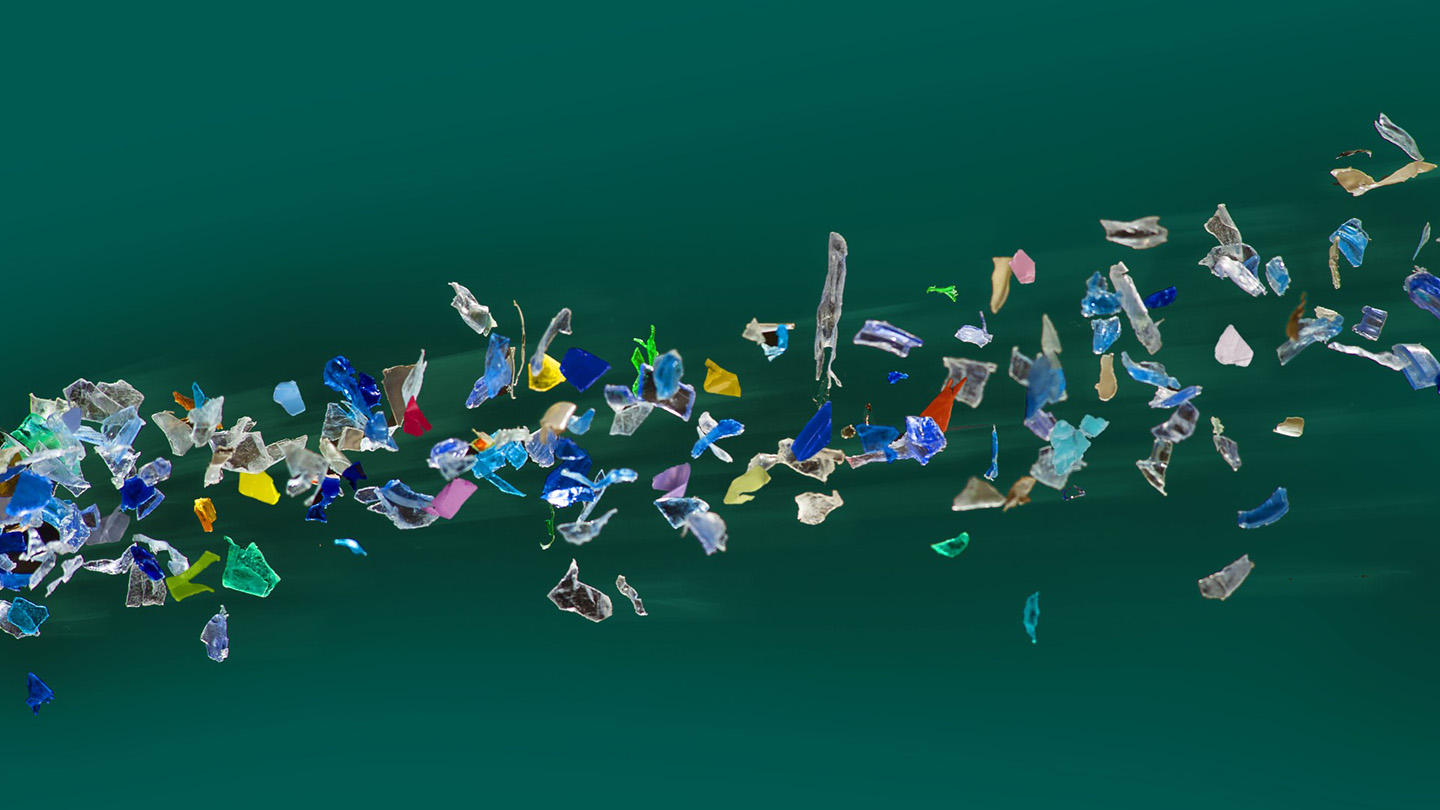

Take Your Plastic Sorting to the Next Level

Our optical sorters detect and reject raw material that either has non-conforming colors or shapes sorting with extreme precision and sorting speed. The combination of cutting-edge optical technology and mechanical engineering ensures best-in-class performance. Advanced cameras equipped with RGBN, SWIR, and UV technology analyze materials for their chemical nature. With insights into composition at the molecular scale, sorting parameters reach unparalleled accuracy. Our highly specialized technology can drive operational success for your plastic business both in terms of quality and operating costs.

Dry Recycling Process

With our Delta Screen Cleaner and SEA.HY

Watch how, unlike traditional water-based sorting plants, the Plastisavio recycling plant operates on a dry treatment approach, significantly enhancing efficiency and sustainability. Processing materials from the WEEE circuit, with a focus on end-of-life electrical and electronic products (particularly refrigerators), our Delta Screen Cleaner, and SEA.HY Optical Sorters achieve revolutionizing purity levels in material separation 99.9% purity of the sorted polystyrene. Read more about how this plant minimizes waste, reduces energy consumption, and strengthens its value chain by producing raw materials internally - by clicking here.

HDPE & PP Flakes Sorting

Forever Plast S.p.A. new optical sorting line includes a combination of seven Cimbria Optical Sorters to efficiently select both polymers and colors in the same processing line. Five SEA.IQ PLUS and two SEA.HY Optical Sorters ensure the best sorting of polyethylene from polypropylene and other polymers, as well as the separation into different streams of color.

Read more about how this leading company in the plastic recycling industry is revolutionizing the sorting and purification process of HDPE and PP flakes, using Cimbria’s world-leading optical sorting technology - by clicking here.

PVC

Sorting PVC waste is challenging due to its color similarity to some rubbers. Infrared spectroscopy allows optical sorters to differentiate PVC and rubber molecules invisible to the naked eye but distinguishable in their infrared spectra. By detecting these subtle spectral fingerprints beyond visible light, infrared cameras enable the separation of not only black and white plastics but also primary color variants for a complete recycling of all PVC.

PET

Selecting high purity PET requires stringent sorting. To achieve maximum purity, optical sorters combine infrared spectral analysis to identify chemical composition at a molecular level, with traditional RGB camera vision. The combined technologies allow our sorters to precisely target and recover pure PET fractions for recycling through discrimination of both color and chemical fingerprint for an excellent quality production.

HDPE

Separating HDPE from other materials is critical to ensure full recycling of incoming mixed plastics streams. Optical sorters not only distinguish between different polymer types using infrared spectroscopy but also further sort each material by color. This allows the complete separation of HDPE into pure color-specific fractions like white, black and colored. Achieving such granular sorting of plastics by type and color maximizes high-quality recycling outputs.

MINERALS

Optical sorting of minerals is highly complex due to their similar appearances despite compositional differences. It is crucial to identify each mineral's exact chemical makeup as they are valuable materials requiring pure, uncontaminated separation. Our advanced systems analyze minerals at a microscopic level to perfectly segregate economically important mineral streams for use as optimized feedstocks in industries like electronics, automotive and construction.

WOOD CHIPS

Sorting wood chips presents unique challenges due to their irregular shape and texture, as well as to the variations in wood density and moisture content. Their complex and inconsistent physical properties make them difficult to identify and separate using traditional automated methods. With our advanced optical sorters, different types of wood are perfectly separated and the quality of the final production very much increased.

METALS

Metal sorting ensures precise identification and separation of a wide range of metals, including ferrous metals like iron and steel, non-ferrous metals such as aluminum, copper, brass, bronze, zinc, precious metals like gold, silver, and platinum as well as rare earth metals. This not only enhances productivity but also improves the overall quality of metal products, reduces waste, and enhances recycling efforts.

R-PET Flakes

Ensuring the future of food packaging

The video shows the cutting-edge Plastisavio plant for recovering high-quality PET post-consumer materials. This processing plant, designed and supplied by Cimbria, includes a Cimbria DELTA Screen Cleaner, removing fine and light fractions, and a Cimbria SEA.HY Hyperspectral Infrared Optical Sorter, separating foreign polymers (PVC, PS, PC, PA, PO, etc.), foreign bodies (wood, glass, metals, etc.), and non-compliant colors (black, brown, green, etc.) from PET flakes, and a Cimbria SEA.CX Optical Sorter, sorting the products into two homogeneous fractions of high-quality clear PET and light-blue PET.

Put Your Products to the Test

Send us your toughest sorting challenge. Let our experts help you with your toughest sorting challenge by signing up for a free test in our lab and recommend the best solution.

THE POWER OF AI

Your business is driven by quality and precision. You need to maximize the good and minimize the bad to succeed. And it all starts with a precise recipe. Getting it right takes time and years of experience. Until now.

Introducing BRAIN. The AI-powered software drives optical sorting to the next level of accuracy and automation. With BRAIN, you can create the most complex recipes in a flash. AI ensures parameters continuously self-optimize for maximum efficiency.

High-Tech Made Easy

An outstanding user experience with the latest technology in the HMI

Simplified screens, increased visibility and improved graphics make it easy for the user to set dedicated programs. You can easily create efficient programs by using your password, retrieving data remotely to optimize performances. The customizable home screen makes sure your machine is easily set to match the way you operate.

Exclusive 24/7 Service

Expert support is crucial for successful optical sorting. Cimbria and our authorized partners offer exclusive 24/7, 365-day service to ensure maximum productivity and quality. With our team by your side, you have a reliable partner to help you succeed.

Related Articles

At Cimbria, we design, develop, manufacture and install custom-built solutions, from complete processing lines to large turnkey projects with highly advanced automation and management information systems.

Start your journey with Cimbria today

Want to know more about how our solutions can help grow your business?

Fill in the form and leave a note about what you would like to talk to us about and we will get in touch with you.